Week 6 (21 June – 27 June)

A multitude of our parts has been printed/arrived from China!!!

Firstly, our belt-driven actuators arrived. Some potential issues we identified are the lack of a belt tensioner as well as the gantry plate being attached too tight to the aluminum profile, causing the movement to be uneven.

Secondly, our first prototype of the actuator base adapter mount has finished printing, some issues we discovered after testing include a very cumbersome installation process and weak spots in its structural integrity when a lateral force is applied. Our second prototype of this adapter will have to be reinforced as well as implement a simpler way of installing it to the linear actuators.

Thirdly, the optical breadboard arrived, we quickly designed some standoffs to be mounted with foam to be attached to the optical breadboard. The optical breadboard seems well made and attaches well to the base mounting adapters we previously made.

Fourth, the 2nd prototype of the platform plate finished printing. An issue we failed to identify previously in our first prototype is also present in this prototype. The holes we designed to place the ball joint attachments have too much tolerance and require double-sided tape in order to stick the joints to the plate. This results in uneven positioning of the ball joints which would lead to less precise motion of the platform. Our 3rd platform plate prototype will need to have smaller tolerances in order to allow us to friction for the ball joint attachments for more precise movements.

Fifth, the 1st prototype of our actuator platform adapter has been printed, a similar issue to the platform plate where the tolerance of the holes for the ball joint is too large is present. We will have to address this issue in the next revision of this part.

Finally, the 1st prototype or about fixed rods have been printed. However, due to print issues, the rods all have marginally different lengths which will contribute to the inaccurate movement. Thus, these rods will have to be re-printed eventually.

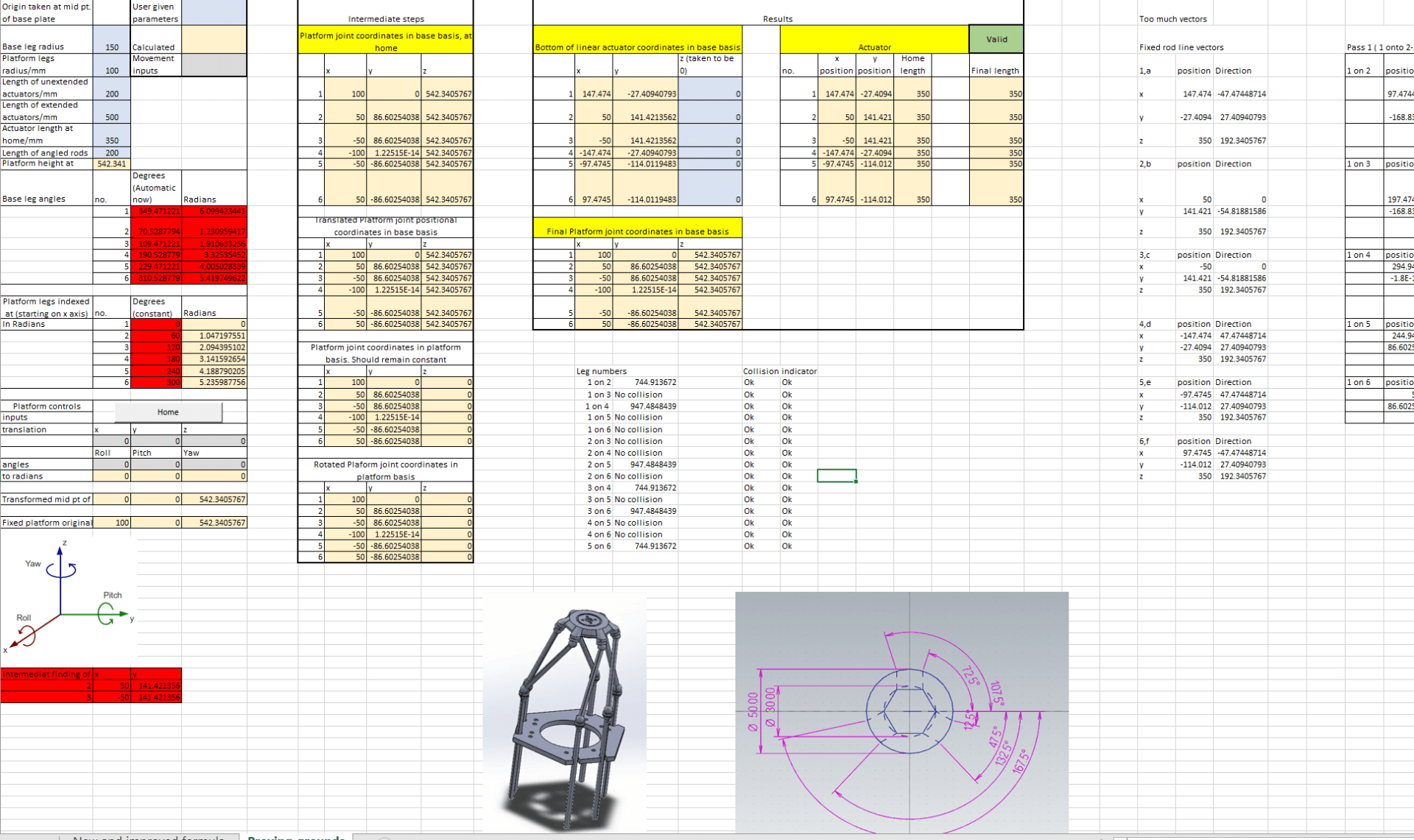

In regards to the conversion of inputs to actuator lengths, we decided to use python to run the script to implement the math of the platform. Currently, the code is unoptimized and buggy, and lacks many features such as homing, direct input, emergency stop, and start/stop sequences.

The coding team has to modify the existing Marlin code in order to implement these features. Simultaneous homing is one such feature that is not available in Marlin at all and will have to be coded into the source code of Marlin.

The hardware team installed limit switches to allow the actuators to home, however, the actuation points of the limit switches are not consistent, resulting in inaccurate homing. A part has to be designed and fabricated to be attached to the gantry plate to ensure the actuators home accurately.

An updated and improved stable motion study that uses belt actuators has been completed by the hardware team, this will help us to model the other parts needed to optimize the movement of the platform.

A simple GUI application using typescript is currently in development, this will serve as the interface for our final platform. We intend for his application to be an all-in-one package that handles serial port connections, streaming data, our math logic, and interpreting inputs from the user.

1st prototypes of actuator platform adapter

1st prototype of actuator mounting base adapter

1st prototype of actuator base mounting adapter with actuator attached

Hexapod GUI

Revised motion study

2nd platform prototype