From the page on the Working Principle of the Hyperloop, it is evident that the main objective to be met is to allow the vehicle to reach a high-enough speed by overcoming magnetic drag and hence levitation can occur.

Throughout the project, achieving this was a challenge. In attempting to resolve this problem, we considered 3 alternatives before arriving at our final design.

Note: Based on preliminary COMSOL modeling, it was estimated that the minimum velocity required before levitation could occur was about 10 m/s.

Option I: Using GPE

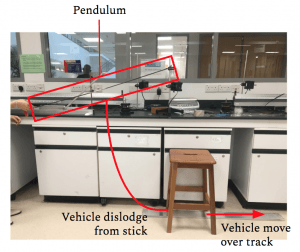

We first looked at using gravitational potential energy (GPE) as a low-tech means to vary the velocity of the prototype as part of the initial testing of the prototype. The setup made use of the vehicle as a detachable end of a ‘pendulum’. To the end of the rod, a magnet was attached; whereas a magnetic object was attached to the top of the vehicle.

When the vehicle (still attached to a rod) was dropped from a certain height, it would fall and eventually detach from the rod when the rod makes impact with a lab stool at the lowest point of the fall. At that point, an aluminium sheet would be placed. When the vehicle detaches from the rod, it will start traveling at its peak velocity (from fall) over the sheet.

Below is a video to demonstrate how the setup works.

Note: The loosely-attached rod dislodges from the vehicle (on impact with the chair) to prevent the upward swing of the prototype after reaching the lowest point and peak velocity.

However, we ran into a few problems with this setup.

- Difficulty in dislodging vehicle properly: The impact on the chair caused much energy loss, and thus a loss of speed as well. Additionally, it was hard to ensure that the vehicle would be dislodged and continue moving in a straight line over the aluminium sheet.

- Large magnetic drag: As the vehicle was only given an initial boost in speed, magnetic drag took over very quickly. This caused ‘braking’ of the vehicle instead of allowing it to move over the track at its original speed.

From these aforementioned challenges, it is evident that levitation could not occur. At the same time, it seemed impractical to use this setup as a means to build up the speed of the vehicle. If we wanted to increase its initial velocity, that would mean building higher and higher pendulums / setups. This would be unrealistic.

Due to the presence of large magnetic drag (in part because of how strong the magnets are), we also realised that a constant horizontal force should be applied on the vehicle instead of just an initial boost.

Option II: Motor-driven Vehicle

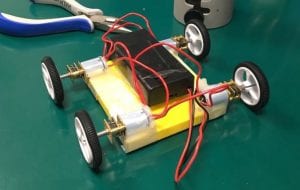

Realising that we needed a constant horizontal force applied to the vehicle, we started considering other options. One of them was to build a motor-driven vehicle.

To build the above setup, we attached high-power micro metal 30:1 gear motors (each motor: 1000 rpm @ 6 V) to each of the 4 rubber wheels. We kept the vehicle as light as possible to increase the maximum speed to be reached. To the top of the vehicle, we attached a 9V battery held in a battery holder.

While the vehicle was now able to move more quickly, and the high-power motor was capable of carrying a heavier load, the vehicle still could not reach the required speed. Magnetic drag was still significant and could not be overcome.

Other challenges that arose were:

- Lack of vehicle stability: It was difficult ensuring the vehicle moves along a linear path — to achieve this, the placement of wheels had to be very precise.

- Significant time was needed for the motors to reach their top speed, which even when achieved, was still not enough to overcome magnetic drag.

- Maximum speed was limited by the added weight of the battery: A vicious cycle would result if we tried to counteract this. Say, if we were to use more powerful motors, a larger battery would be needed, leading to a heavier setup, and so on.

The failure to reach the required velocity taught us the importance of the weight of the vehicle. We thus had to think of a way to make the vehicle move faster without adding more weight to it.

This led us to Option III, in which we used external forces to move the vehicle, instead of allowing the vehicle to be self-propelling.

Option III: Drone Motor-Controlled Timing Belt

In this setup, we attached our vehicle to a timing belt which would be pulled by a high-power, high-speed drone motor over an aluminium sheet. This not only allowed us to increase the power and speed of our vehicle without added weight, it also allowed us to control the speed of the motor and thus the vehicle by connecting the motor to an ESC.

Below is a video demonstrating how the setup works:

With this setup, we were able to allow the vehicle to move quickly enough to overcome magnetic drag. This overcame the main challenge that we were facing — building up speed. From the slow-motion video, it is also evident that there was some vertical displacement of the vehicle.

However, it was unclear if said vertical displacement was due to the quick but unstable movement of the timing belt, or magnetic levitation of the vehicle. Other challenges included:

- Difficulty in observing levitation: The high speed of the vehicle and the short track limited the time allowed to observe if levitation had occurred.

- Lack of stability: As the timing belt was not taut, the vehicle was prone to horizontal disturbances, causing unstable movements.

Takeaways

Based on the takeaways from these 3 setups, we came up with a set of criteria that our setup / vehicle had to meet.

- High-power setup: to overcome initial magnetic drag and reach velocity needed for levitation

- Capable of sustaining high speed: to prevent braking

- Allows easy observation of levitation

- Stable setup to prevent other factors from affecting observation

- A track that allows the buildup of speed

Simultaneously, we also tried to tailor the design of our vehicle and track according to the shifts in direction of our project. We also quickly realised that perhaps moving the vehicle in a linear fashion was not the most practical setup. To read more on these efforts, please read the next section on the Planning of our Prototypes.